News

RAVAN AIR Soars Inside a Hydroelectric Giant:

Innovative Penstock Inspection in Columbus, Nebraska

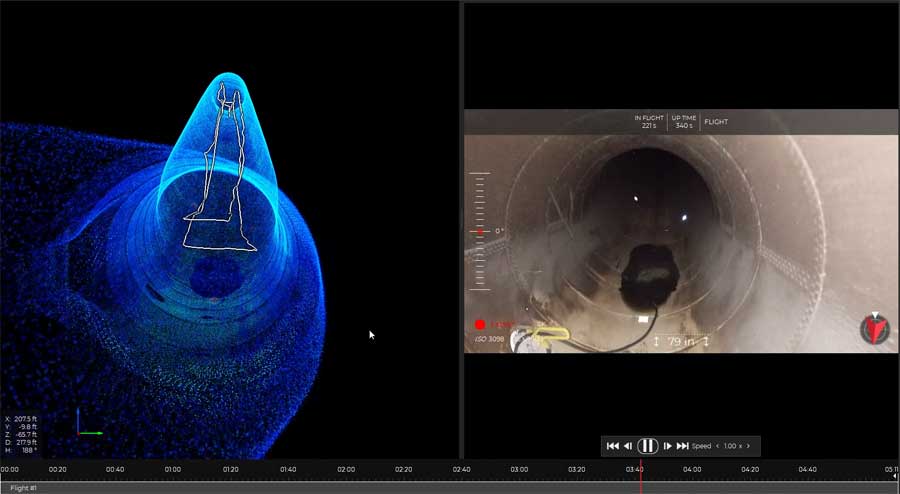

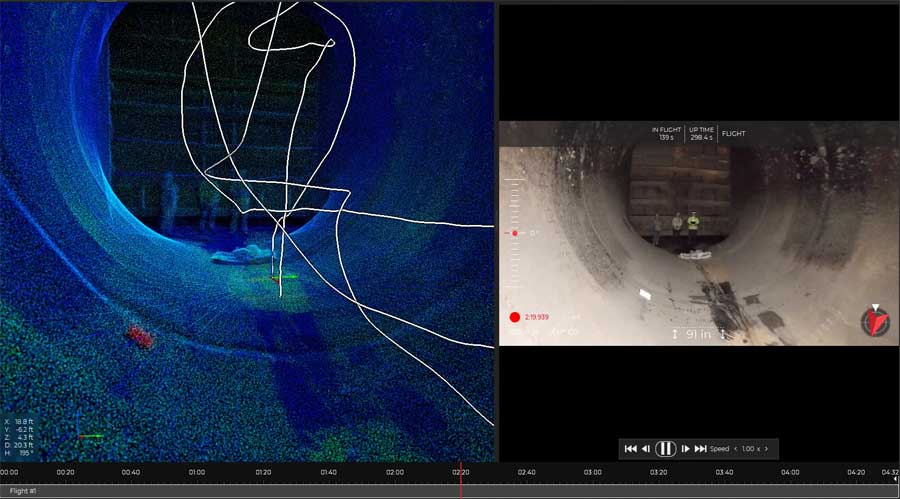

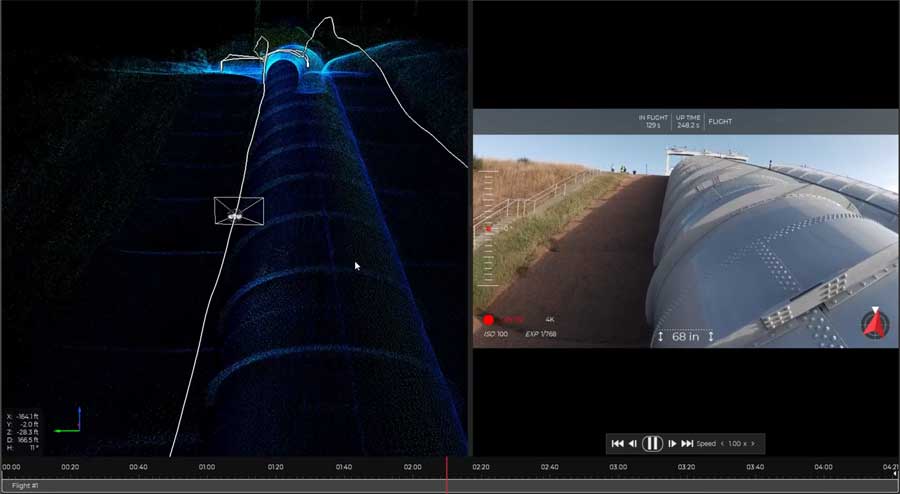

Columbus, Nebraska – RAVAN AIR recently demonstrated the power of cutting-edge technology for infrastructure inspection, successfully completing a challenging project within a hydroelectric dam’s penstock. This impressive feat showcases the company’s ability to leverage drone-based LiDAR (Light Detection and Ranging) to capture highly detailed data in confined and difficult-to-access spaces.

The project focused on inspecting a riveted steel penstock, the large-diameter pipe that channels water to the dam’s turbines. This particular penstock, a crucial component of the hydroelectric facility, measured an impressive 15 feet in diameter and stretched 326 feet in length, making internal inspection a complex undertaking. The damaged portion of the penstock was inaccessible by ladder or scaffolding, making a drone inspection the only practical and safe alternative to a hazardous confined space entry. The riveted construction added another layer of complexity to the inspection, requiring meticulous data capture to assess the condition of the seams and joints.

For this challenging task, RAVAN AIR deployed the Flyability Elios 3, a specialized underground inspection drone. This robust and agile drone is designed specifically for navigating confined spaces and capturing high-quality data in challenging environments. Equipped with advanced LiDAR technology, the Elios 3 captured millions of data points, creating a precise 3D point cloud of the penstock’s internal structure. This detailed data provided invaluable insights into the condition of the pipe, revealing any structural anomalies, potential weaknesses, areas of corrosion, or issues with the riveted joints.

“The level of detail we obtained from the LiDAR data was remarkable,” explained Dave Rock, pilot at RAVAN AIR. “The point cloud allows for precise measurements and a thorough analysis of the penstock’s condition, giving the client a comprehensive understanding of its integrity. The Elios 3 performed exceptionally well in this challenging environment.”

This non-destructive inspection method offered several key advantages:

- Enhanced Safety: While confined space entry was necessary, the drone inspection played a vital role in mitigating risks. This non-destructive approach provided a safe and efficient way to assess the damage that was otherwise inaccessible.

- Increased Efficiency: The drone-based inspection was completed quickly and efficiently, minimizing downtime for the hydroelectric facility.

- Comprehensive Data: The high-resolution LiDAR data provided a much more detailed picture of the penstock’s condition compared to traditional inspection methods.

- Cost-Effectiveness: Drone-based inspections can often be more cost-effective than traditional methods, especially when considering the costs associated with confined space entry.

This penstock project highlights RAVAN AIR’s expertise in pairing advanced technology with a skilled team to address infrastructure challenges. This type of inspection is crucial for ensuring the long-term safety and reliability of hydroelectric facilities, playing a vital role in maintaining our energy infrastructure.

As technology continues to advance, RAVAN AIR is at the forefront, developing innovative solutions for the inspection and maintenance of critical assets.

Contact us for an assessment of your project today. Visit our website >>

About RAVAN AIR

RAVAN AIR is based in Conneaut Lake, PA, and offers a full line of underground, aerial and above ground inspection services serving the oil and natural gas, landfill, utility and construction industries. RAVAN AIR is constantly looking at innovative ways to transform manual, time consuming tasks into an automated, time-saving mission. RAVAN AIR was created by and for people in the natural gas industry.