News

How Drone Technology is Changing Oil and Gas Infrastructure

As many of you know drone technology had grown by leaps and bounds in the recent years. Aerial surveys can now be done with survey grade accuracy utilizing Lidar. Volume calculations can be done with ease for material stockpiles or landslides. Utility inspections using a high resolution camera and zoom lens can be done from a safe distance high above, and HD video with geo referencing can keep operators aware of their infrastructure status and where any problems may be arising. Drone mounted infrared cameras can be used for analyzing solar panels and assisting fire fighters.

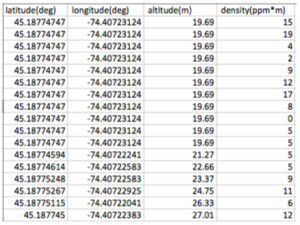

Now Drone Technology has been taken to another level. Utilizing a drone mounted infrared laser scanner or infrared gas camera, you are now able to perform accurate leak survey over natural gas pipelines and infrastructure, helping to save time, reduce risk to employees and improve compliance. The laser system detects natural gas leaks by emitting an eye safe infrared laser at particulate wavelength and then analyzes the light reflected back from the ground to determine how much was absorbed by the methane in the natural gas. The gas concentration is measured in column density and expressed in PPM x Meter. Typical surveys are conducted at a height of 30 meters giving an 11” wide scan at ground level. The information collected during the flight can be then imported into any GIS system and or Google Earth. A spreadsheet is provided listing PPM/M, GPS coordinates, altitude, and a date/time stamp. An HD video is taken during the survey to document the area being surveyed and included in the report given to the client. The data collected meets the requirements of the PUC for leak survey.

The infrared gas camera utilizes a cooled infrared sensor to detect temperature differences as gas rises from the ground or other infrastructure. This system can help complete leak survey on bridge crossings or over water as well.

Infrastructure inspections from wind turbine blades to wireless communication towers, utilities hung on bridges, all of these can be reliably inspected with photo documentation for compliance in a very cost-effective way. The drone uses a powered gimbal to get the correct angle for the perfect shot to document the inspection. If gaining access to right of ways is an issue than utilizing a drone can take that headache away. This again can cut costs allowing the operator access with little or no disruption to facilities and land owners. This can also cut down on fees associated with accessing facilities (i.e. railroad access).

Surveying using drones has come a long way as well. The newest technology provides up to +/- 2 cm accuracy surveys using either LIDAR or photogrammetry and control points. Photogrammetry uses HD photos stitched together to create a high resolution image which can then be converted into a point cloud or many other formats that can be used in AutoCAD or other GIS software. Photogrammetry does better with little to no vegetation cover but can give similar results to LIDAR. LIDAR(light detection and ranging) survey uses pulsed laser to send thousands of laser pulses per second and recording the distance of the return pulses to produce a point cloud that can be uploaded into any number of software applications to produce accurate survey maps. LIDAR makes it easier to perform an aerial survey through vegetation with minimal processing. Post processing times vary but LIDAR allows quicker turnaround time for surveys. As with any technology, LIDAR is more expensive up front but that can be made up with less post processing time to achieve great results.

Ravan AIR is based in Conneaut Lake, PA and offers a full line of drone technology services serving the oil and gas industry as well as other utilities. They specialize in methane leak detection, but they also do photo and video inspections, and aerial survey. Ravan AIR is constantly looking at innovative ways to transform manual, time consuming tasks into an automated, time saving drone mission. Ravan AIR was created by and for people in the natural gas industry.